The vibration of asynchronous motor is the focus of motor structure design at present. It is composed of electromagnetic vibration, mechanical vibration and gas vibration.

Electromagnetic vibration: the interaction of the magnetic field in the air gap of the motor generates electromagnetic force varying with time and space on the rotor and stator, causing the motor to vibrate.

Mechanical vibration: it is the vibration caused by the imbalance of rotor, bearing and other mechanical structures or devices.

Gas vibration: it refers to the vibration caused by the air flow in the ventilation parts of the motor or aerodynamic force.

The electromagnetic vibration of asynchronous motor is the main vibration source of many large and medium-sized motors. Since the electromagnetic vibration of the motor is the result of the interaction between the electromagnetic field and the motor structure, using the magnetic solid coupling vibration theory to study the electromagnetic vibration of the motor is a more effective method to find the mechanism of the electromagnetic vibration of the motor and solve the electromagnetic vibration of the motor. Because the electromagnetic force is the excitation source of the electromagnetic vibration of the motor, and its calculation accuracy determines the calculation accuracy of the electromagnetic vibration of the motor, at present, the numerical analysis method is mostly used to calculate the electromagnetic force of the motor in the research of the electromagnetic vibration of the motor.

The calculation and analysis of vibration and noise of motor structure mainly includes the following parts:

Dynamic analysis: including modal analysis, harmonic response analysis, rotor vibration analysis, coupling vibration analysis of rotor, stator and base, vibration analysis of stator and base, resonance, critical speed analysis and transient response characteristics.

Noise analysis: vibration noise caused by motor vibration, pneumatic noise caused by motor fan, etc.

Multi physical field coupling analysis: electromagnetic, thermal, fluid and structural interaction of motor.

When the motor vibration is more common, use the vibration meter to measure the vibration value of each part along the horizontal and vertical directions, and make corresponding records. Listen to the sound inside the stator cavity of the motor and the rotation sound of the bearing, check the foundation, if there is no obvious abnormality, and take the method of idling the motor separately from the dragged machine to judge whether it is the vibration of the motor itself or the vibration caused by dragging the machine. In the production process, it will be found that after the motor is repaired, the magnetic potential of the three-phase winding is asymmetric due to various reasons, and the vibration of the motor is not very obvious under no-load or low load. Once the load of the belt is increased, the vibration of the motor will gradually increase.

We often cut off power in production to distinguish the vibration caused by electromagnetic or mechanical reasons. The power-off method refers to the sudden power-off of the motor running at the rated speed. If the vibration is suddenly reduced, it can be judged as caused by electromagnetic reasons. If the vibration value changes little, it may be caused by mechanical reasons.

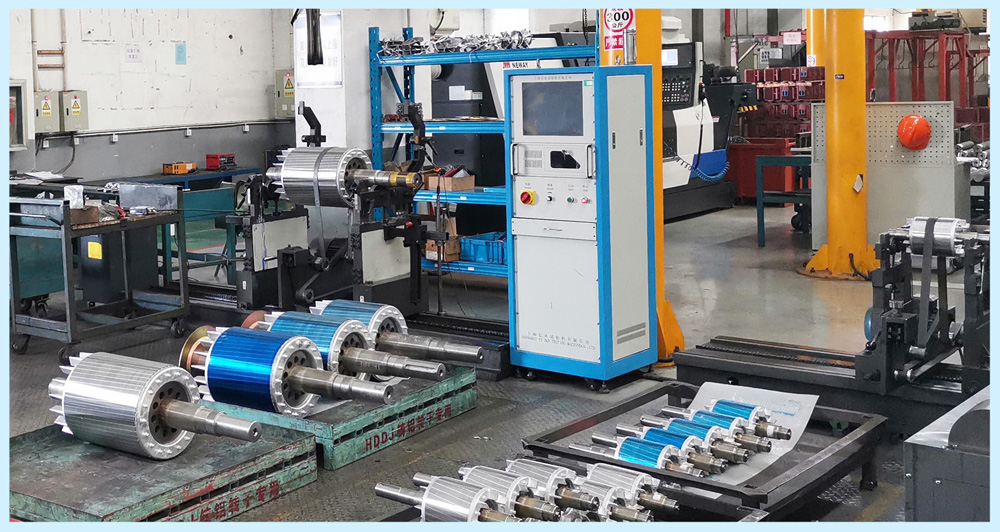

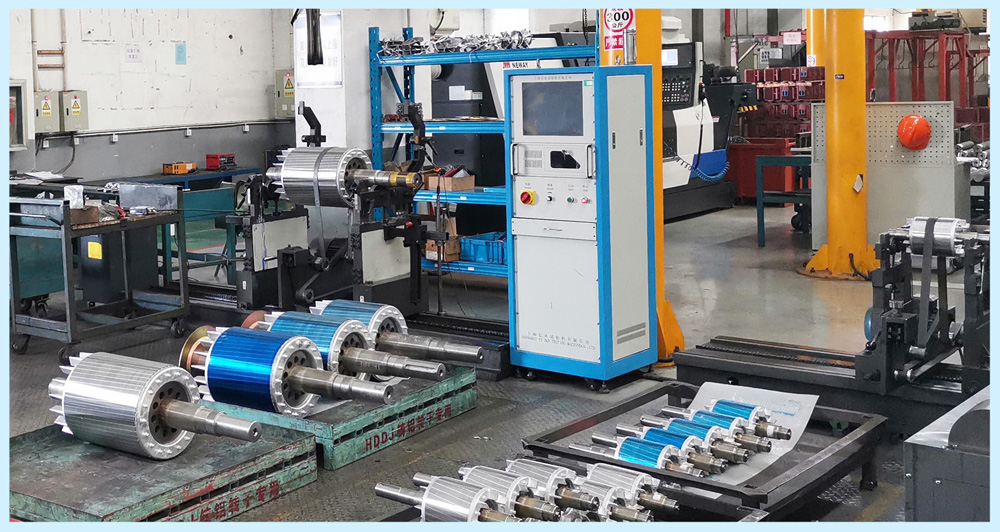

For the vibration caused by machinery, if the bearing is worn, replace the bearing of the same model immediately; If the rotating shaft is deformed, the shaft must be calibrated or replaced; If the fastening at the corner of the ground is not firm, it will be tightened again. The foundation strength is not enough, and the height of the bedplate looks like a small problem, but it is often the most direct cause of vibration. In addition, poor rotor balance is also the root cause of vibration. When the motor leaves the factory, the rotor has passed the calibration. However, when repairing the motor, we often don't pay attention to the link of marking and scale, and dismantle a part of the dynamic balance calibration without authorization. After reloading, it will inevitably lead to poor dynamic balance and motor vibration The only way to do this is to rebalance.

For the vibration caused by electromagnetism, the power supply shall be checked. Check whether the three-phase voltage is balanced, whether the three-phase current is balanced by clamp current measurement, whether there is single-phase operation, etc. it is found that the terminal wiring in the motor junction box is not fastened firmly and often burned out, resulting in single-phase operation and other problems. The inspection force of this place should be increased and eliminated. If it is found that the three-phase current is unbalanced and the gauge needle swings high and low when measuring with clamp current, it indicates that the cage bar of the rotor is broken. At this time, the electric vehicle shall be stopped immediately, the power supply shall be cut off, and the rotor shall be pulled out for patrol inspection and repair. In addition, the resistance value of the three-phase stator winding shall also be measured to check whether the winding is symmetrical. If the resistance value is unbalanced, it indicates that there are open welding parts. The rotor shall also be pulled out for inspection and re welding.