In motor manufacturing, process fluctuation factors often have a great impact on the quality of the motor. On the one hand, it affects the operation performance of the motor, and on the other hand, it affects the assembly quality of the motor. The influence of motor manufacturing process on motor performance index is relatively complex. Often, a motor performance index is related to several process fluctuation factors. Different types of motors have different characteristics, which must be analyzed according to specific conditions.

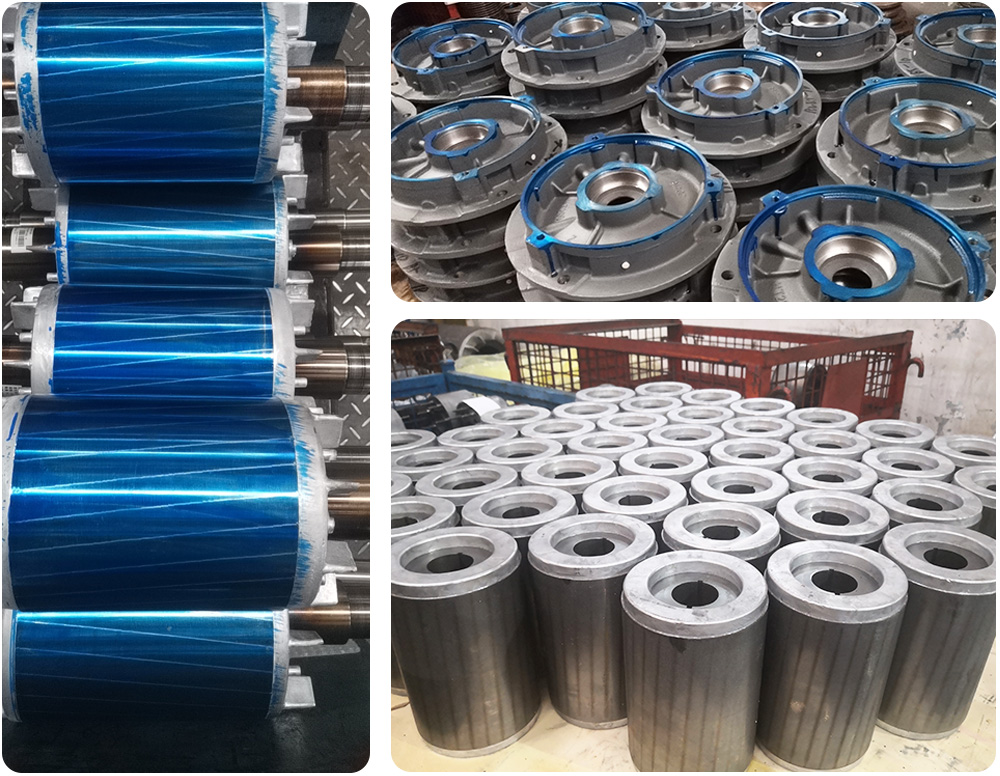

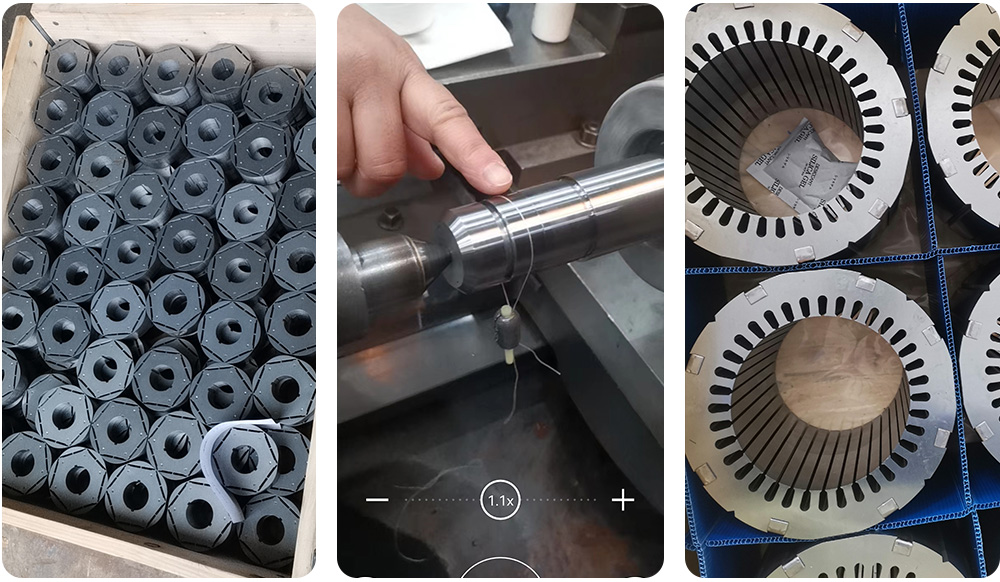

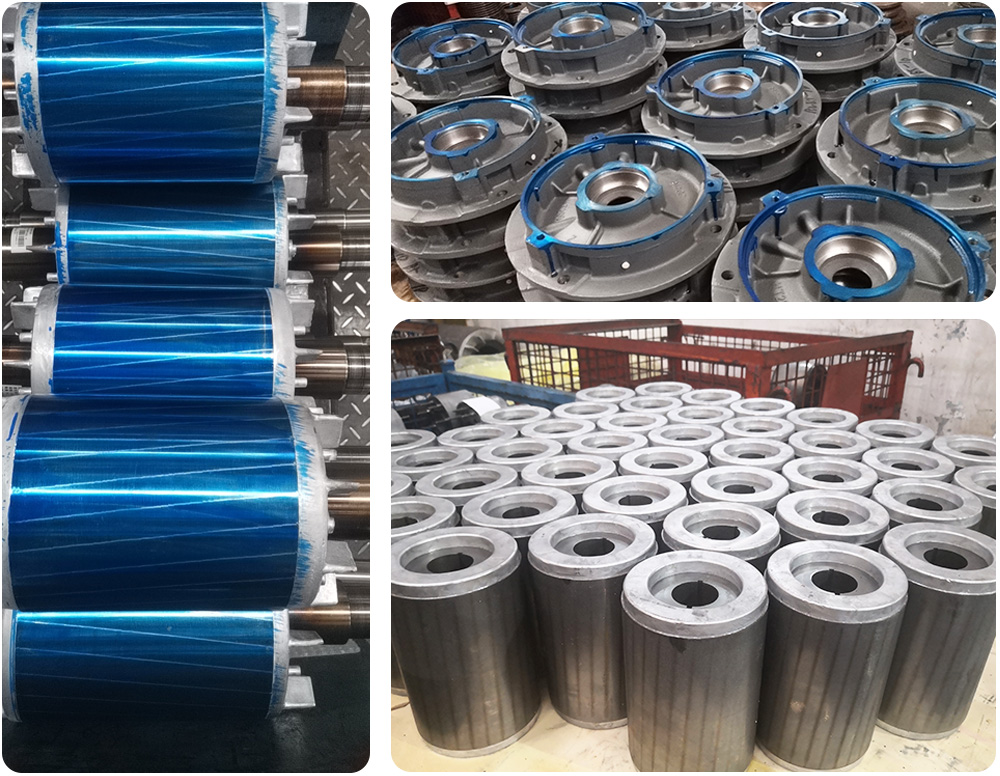

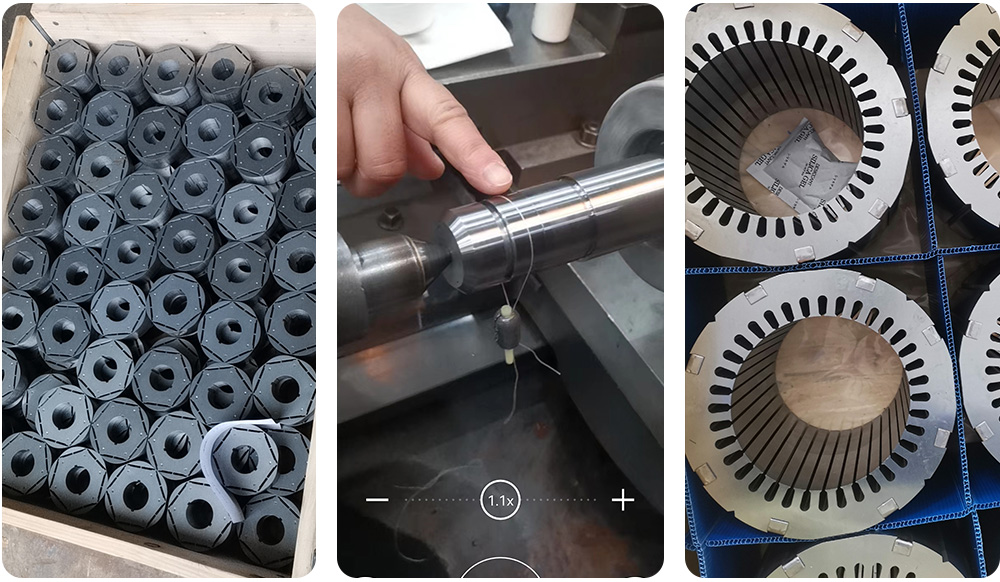

In motor manufacturing, the machining quality of the base, end cover, shaft, stator and rotor core is high, which is an important factor for good motor quality. If the size error occurs when machining these parts, the motor quality will be reduced, and in serious cases, the motor will be unable to operate.

For asynchronous motors, turning the inner circle of the stator core or filing the stator slot will lead to increased iron loss, reduced efficiency and increased temperature. When the outer circle size of the rotor core is small, the air gap will be larger than the design value, which will lead to the reduction of stator harmonic leakage reactance and rotor harmonic leakage reactance, and the total leakage reactance of the motor will decrease, so the starting current will increase. At the same time, it also leads to the increase of air gap magnetomotive force and no-load current, the decrease of power factor, the increase of stator current and stator copper loss, the decrease of efficiency and the increase of temperature rise. When the size of the outer circle of the rotor core is large, the air gap will be smaller than the design value, which will lead to the increase of stator harmonic leakage reactance and rotor harmonic leakage reactance, thus the total leakage reactance of the motor will increase, resulting in the reduction of the starting torque and maximum torque of the asynchronous motor, the increase of the reactance current at full load, the increase of rotor current and rotor copper loss, the low efficiency, the rise of temperature, and the increase of slip. When the deviation of cylindricity, coaxiality and end face runout at the base spigot, end cover bearing chamber and spigot, bearing retainer, inner circle of stator core and outer circle of rotor core is too large, the air gap will be uneven, which will cause unilateral magnetic tension of the motor, causing vibration and noise. In serious cases, the outer circle of the rotor will rub against the inner hole of the stator, causing local burns to the motor. When the axial offset occurs between the stator and the rotor core, it will reduce the effective length of the core, increase the no-load current and reduce the power factor. When the surface roughness of the inner circle of the ordinary enclosed motor frame is too large or there are too many defects, the stator core and the frame will have poor contact, and the thermal resistance will increase, which will lead to higher temperature rise of the motor.

The machining dimensions of the base spigot, end cover bearing chamber, spigot, bearing block and other parts are out of tolerance, which makes the motor difficult to assemble, operate flexibly or lock. The dimensional accuracy and form and position tolerance of the bearing chamber and the bearing retainer are out of tolerance, which will deform the inner and outer circles of the rolling bearing, generate vibration and noise, increase the friction loss of the bearing, and increase the temperature rise of the bearing.

For synchronous generators, if the air gap is too small, the synchronous reactance will be too large, the short circuit ratio will be smaller, and the voltage change rate of the generator will increase; The stability of parallel operation is poor; The surface loss of rotor increases; Reduced efficiency. If the air gap is distributed along the periphery, the line voltage waveform will be distorted and the transmission line loss will increase.

For DC motor, if the air gap is too large, the excitation current and excitation loss will increase and the efficiency will decrease. If the air gap is too small, the armature reaction will increase, causing the performance fluctuation of the generator or motor. If the coaxiality deviation between stator and rotor is too large, the armature winding will generate circulating current and stray copper loss will increase; Moreover, the current commutation is difficult, and serious sparks appear on the commutator.