The main function of motor bearings is to support mechanical rotating bodies and reduce the mechanical load friction coefficient of equipment during transmission. The operation and maintenance of motor bearings are crucial for ensuring stable operation and extending the service life of the motor. Here are some key maintenance points:

1、Cleaning and maintenance

① Regularly remove oil stains: Use a suitable cleaning agent and soft cloth to wipe the surface of the motor bearings to remove oil stains and impurities. Avoid using overly irritating cleaning agents to prevent damage to the bearing surface.

②Remove dust: Regularly use an air gun or soft bristled brush to clean the dust on the surface of the bearing, preventing dust from entering the interior of the bearing and causing wear.

2、Lubrication management

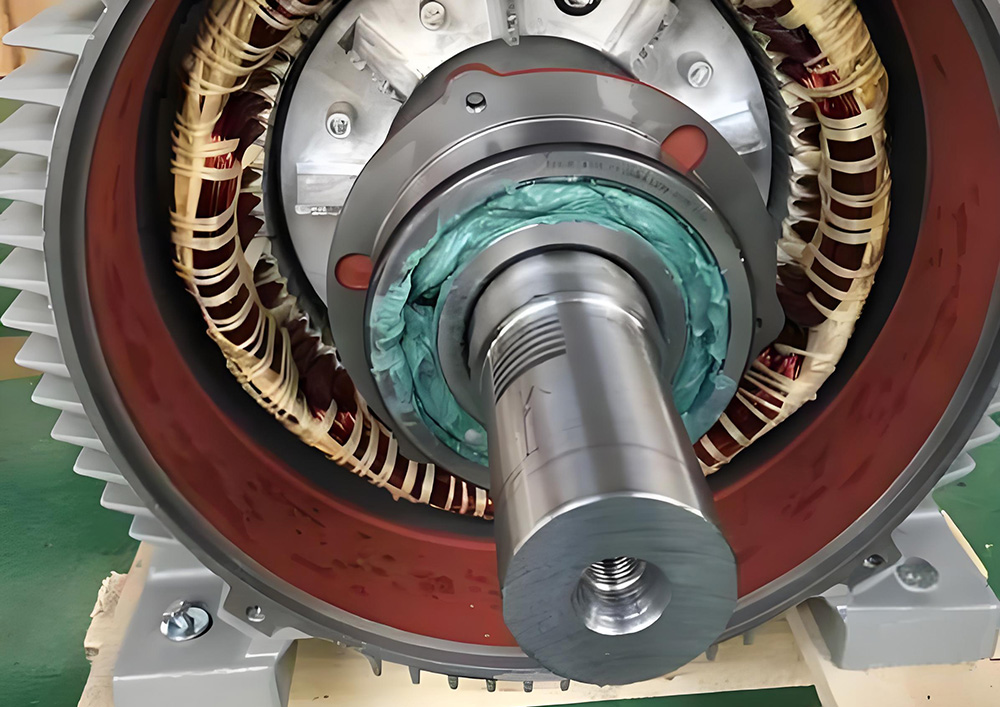

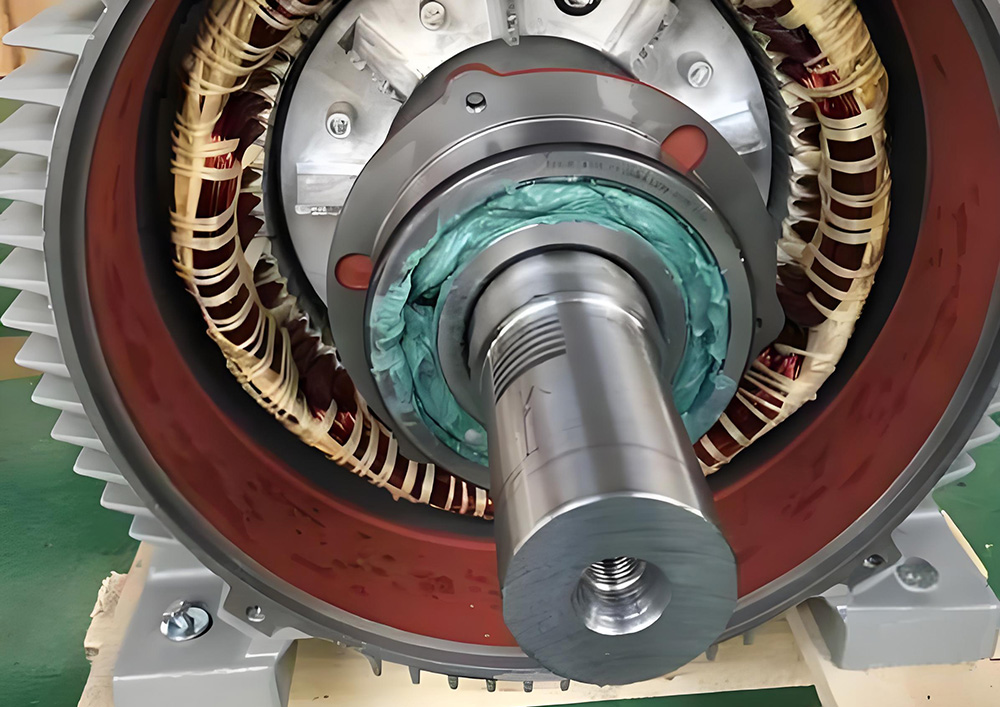

①Check the lubricating oil: Regularly check the lubricating oil condition of the bearings to ensure that the lubricating oil is clean and sufficient. If the lubricating oil is insufficient, it should be added in a timely manner; If contaminated or expired lubricating oil is found, it should be replaced immediately.

②Choose the appropriate lubricant: Select the appropriate lubricant based on factors such as bearing type, load, and working environment. For example, high-temperature environments may require the use of high-temperature resistant synthetic lubricants or greases; High speed bearings may be more suitable for lubricating oil with good fluidity.

③Controlling lubrication amount: Adequate lubrication is key. Insufficient lubrication can lead to increased bearing wear, while excessive lubrication may cause problems such as heating and leakage. For bearings lubricated with grease, the general filling amount is about 1/3 to 1/2 of the internal space of the bearing; For oil lubricated bearings, it is important to ensure that the oil level is within the appropriate range and that the oil can circulate smoothly to all parts of the bearing that require lubrication.

3、Installation and disassembly

① Correct installation: When installing motor bearings, ensure a good fit between the bearings and the bearing seats. Avoid installation that is too tight or too loose to prevent excessive vibration. At the same time, it is necessary to ensure that the installation surface is clean and flat, and that the fitting dimensions with the bearings meet the requirements.

②Careful disassembly: When disassembling bearings, appropriate tools such as bearing pullers should be used to avoid rough disassembly using tools such as hammers that may damage the bearings. During the disassembly process, attention should be paid to recording the installation direction, serial number, and other information of the bearing for reference when reinstalling or repairing.

4、Monitoring and Inspection

①Regular inspection of appearance: Regularly inspect the appearance of bearings to see if there are signs of wear, cracks, corrosion, etc.

②Monitoring operating status: By monitoring parameters such as temperature, vibration, and noise during bearing operation, the health status of the bearing can be determined. Tools such as temperature sensors and vibration analyzers can be used. Generally speaking, during normal operation of bearings, the temperature will remain within a relatively stable range. If the temperature suddenly rises, it may indicate that the bearing has malfunctioned, such as poor lubrication, overload, etc. Abnormal vibration and noise may also be signals of internal component damage, imbalance, and other issues in bearings.

5、Protective measures

①Dust prevention measures: In order to reduce the entry of dust and impurities, sealing or isolation covers can be installed.

②Moisture prevention measures: Bearings are prone to corrosion when exposed to humid environments for a long time, so attention should be paid to keeping the bearings dry. Moisture proofing can be achieved by using moisture-proof cabinets or placing desiccants around the bearings.

In summary, the operation and maintenance of motor bearings involve multiple aspects such as cleaning and maintenance, lubrication management, installation and disassembly, monitoring and inspection, and protective measures. By following these maintenance points, the stable operation and extended service life of motor bearings can be ensured.

Hengda Electric has always been dedicated to the research and development, production, and service of various types of motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.