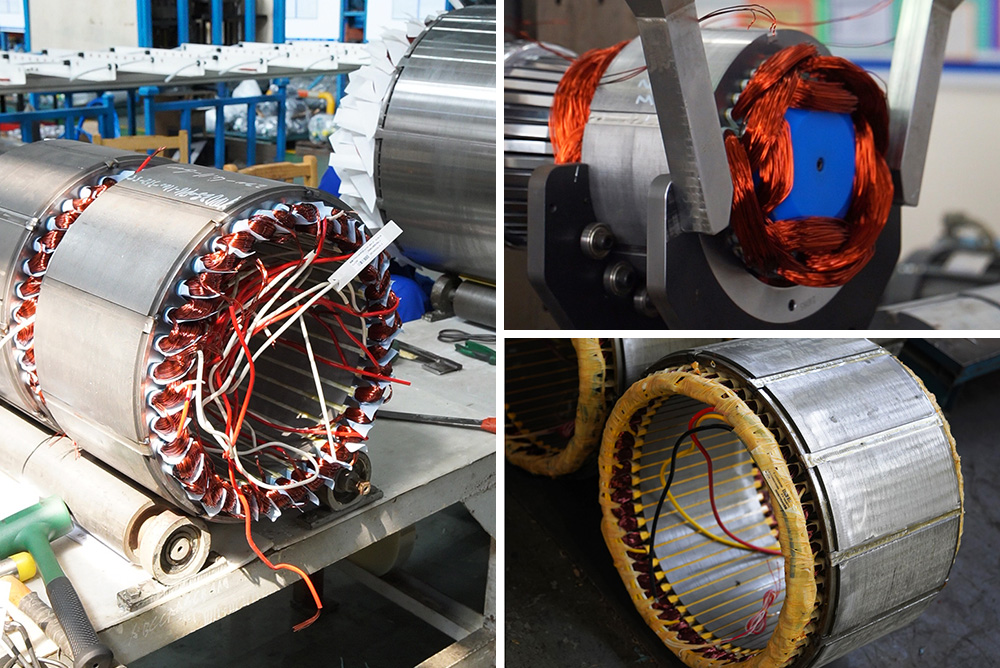

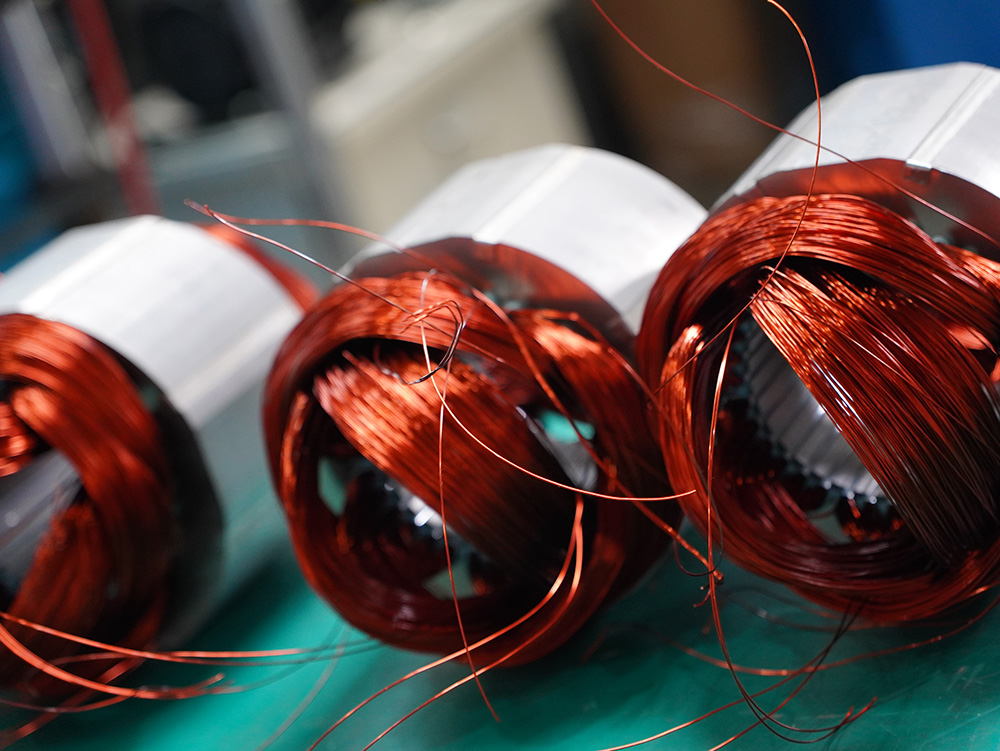

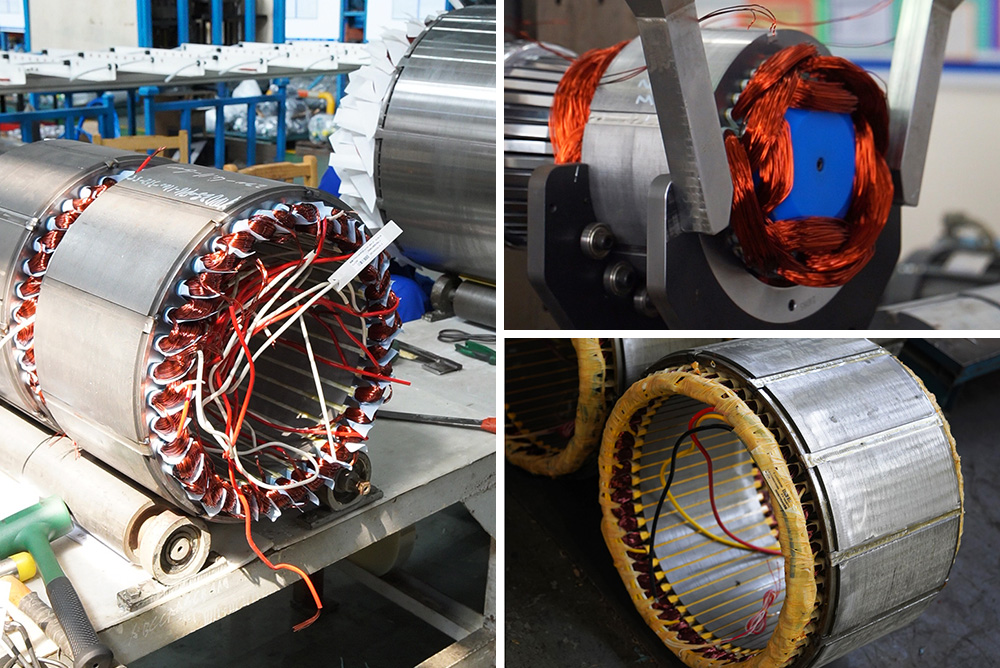

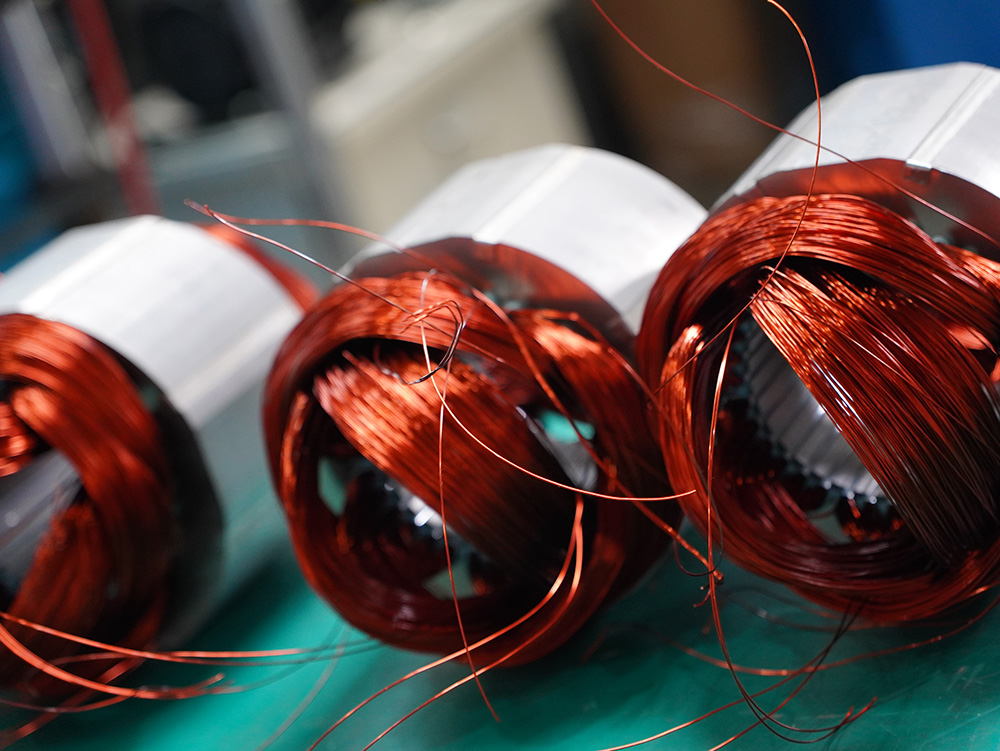

As the core component of modern industry, the stable operation of the winding system of the motor is crucial. However, in practical use, various problems often occur in the winding system, affecting motor performance and even causing equipment shutdown. This article will introduce several common problems with motor windings and their solutions, helping users identify and handle winding faults in a timely manner.

1、Winding short circuit problem

Winding short circuit is one of the most common faults in motors, which can be divided into three types: turn to turn short circuit, phase to phase short circuit, and ground short circuit. Short circuits usually manifest as abnormal motor heating, increased current, and decreased output torque.

Solution:

·Regularly check the insulation resistance of the winding using a megohmmeter. If the resistance value drops significantly, it should be repaired in a timely manner

·When the short circuit point is small, local insulation repair can be used. In severe cases, the entire winding needs to be replaced

·Maintain a dry and clean working environment for the motor to avoid the accumulation of conductive dust

·Ensure that the motor does not operate under overload and prevent insulation materials from overheating and aging

2、Winding open circuit fault

Winding breakage can cause the motor to fail to start or suddenly stop during operation. Common reasons include loose welding points, wire breakage caused by mechanical vibration, or overcurrent burning.

Solution:

·Use a multimeter to check the continuity of the winding and locate the breaking point

·For loose joints, re weld and perform insulation treatment

·Regularly check the fastening of motor wiring terminals

·Install overcurrent protection device to prevent high current from burning out the winding

3、Winding insulation aging

The insulation material will gradually age with prolonged use, manifested as a decrease in insulation resistance and an increase in dielectric loss, which may ultimately lead to short-circuit faults.

Solution:

·Select winding wires with appropriate insulation level according to the working environment of the motor

·Avoid long-term operation of the motor in high temperature environments

·Regularly conduct insulation resistance testing and dielectric loss testing

·Severely aged windings should be replaced in a timely manner to avoid sudden failures

4、Winding moisture problem

A humid environment or water ingress can cause a sharp decrease in the insulation performance of the winding, which can easily lead to short circuit faults.

Solution:

·Pay attention to moisture and water resistance when storing or installing motors

·Damp motors need to be dried, and hot air circulation or low-voltage electric heating methods can be used

·Motors used in humid environments should be selected as moisture-proof or undergo special protective treatment

·Regularly check the sealing condition of the motor to prevent water vapor from entering

5、Winding pollution and dust accumulation

In industrial environments, the accumulation of pollutants such as conductive dust and oil stains on the surface of windings can reduce insulation performance.

Solution:

·Regularly use dry compressed air to clean the dust on the surface of the winding

·Windings with severe oil pollution can be treated with specialized electrical equipment cleaning agents

·Using enclosed motors or installing protective covers in dusty environments

·Avoid using corrosive chemicals to clean windings

Preventive maintenance recommendations

To extend the service life of motor windings, it is recommended to establish a regular testing system (including insulation resistance, DC resistance testing, etc.), record operating parameters and promptly troubleshoot abnormalities, maintain a clean and dry working environment, strictly operate according to rated parameters to avoid overload, and select high-quality winding materials from reputable manufacturers to effectively reduce the risk of faults.

By promptly identifying and addressing winding issues, major motor failures can be effectively avoided, ensuring stable operation of production equipment and reducing maintenance costs. For complex winding faults, it is recommended to contact a professional motor maintenance service provider for handling.

Hengda Electric has always been dedicated to the research and development, production, and service of various types of motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.