The losses of permanent magnet synchronous motors can be divided into four parts, namely stator winding losses, iron core losses, mechanical losses, and load stray losses. It can be divided into three categories in nature: iron loss, copper loss, and mechanical loss.

1. Motor iron loss: When current passes through the stator winding of a permanent magnet synchronous motor, alternating magnetic flux is generated in the iron core, resulting in hysteresis loss and eddy current loss. The magnitude of this is determined by the magnetic flux density in the iron core and the frequency of magnetic flux changes, approximately proportional to the square of the applied voltage. When the voltage and frequency remain constant, the iron core loss remains almost unchanged under no-load and load conditions, hence it is also known as fixed loss, Mainly generated in the stator core.

2. Motor copper loss, electrical energy loss of stator winding and electrical energy loss of rotor winding. Due to the presence of resistance in the stator and rotor windings, electrical energy loss occurs when current passes through, known as copper loss.

3. Mechanical losses

Mechanical losses include friction losses on brushes and bearings, as well as losses caused by wind resistance. If there is a ventilation device, whether it is a built-in fan or an external fan, it should also include the power required to circulate air in the motor and ventilation system (excluding the power required for forced airflow to pass through long or narrow ducts outside the motor during duct ventilation). Friction and wind resistance losses can be determined by measuring the input power of the motor, where the motor operates at an appropriate speed without load and excitation. Usually, friction and wind resistance losses are combined with iron core losses and determined simultaneously.

Bearing friction and ventilation losses. It corresponds to the power consumed by bearing friction and ventilation resistance, and its magnitude is related to the rotational speed.

4. Additional losses in the iron core. It is related to the slotting and relative motion of the stator and rotor, as well as the higher-order harmonics of the stator and rotor magnetic fields.

It is generally believed that for permanent magnet synchronous motors with the same speed, the lower the voltage, the greater the iron loss; A permanent magnet synchronous motor with the same voltage has a higher speed and greater iron loss.

Iron loss of stator and rotor

The permanent magnet of a surface mounted permanent magnet motor directly contacts the air gap, and the large content of harmonics generated during variable frequency power supply will generate a certain amount of eddy current loss in the permanent magnet. Moreover, due to the poor heat dissipation of the rotor, the temperature rise of the permanent magnet will be higher, which can easily lead to the risk of irreversible demagnetization of the permanent magnet. Therefore, it is necessary and important to study the eddy current loss of permanent magnets.

·Motor stator iron loss

The air gap magnetic density cutting of the stator cannot be avoided, and can only be achieved by improving the effective utilization rate of the air gap magnetic density in the electromechanical energy conversion process. For permanent magnet synchronous motors, it means reducing the harmonic of the air gap magnetic density and improving the sine of the air gap magnetic density waveform.

·Rotor iron loss

For permanent magnet synchronous motors, there are two types of structural discussions. The silicon steel sheet structure rotor iron loss is mainly in the eddy current loss of the permanent magnet, while the solid rotor pole structure rotor iron loss includes the eddy current loss of the rotor pole and the eddy current loss of the permanent magnet.

The magnetic flux potential generated by the fundamental current of the stator can be decomposed into two opposite traveling waves. The forward rotating part rotates synchronously with the rotor, without generating eddy current losses on the rotor, but there are still tooth harmonics. The decomposed reverse magnetic flux potential causes the main rotor eddy current. Overall, various harmonic components will exacerbate these eddy current losses. However, considering that the number of harmonics is inversely proportional to their amplitude, only 5-9 harmonics need to be considered generally. Refer to Motor Drive Theory 6.3, 6.4.

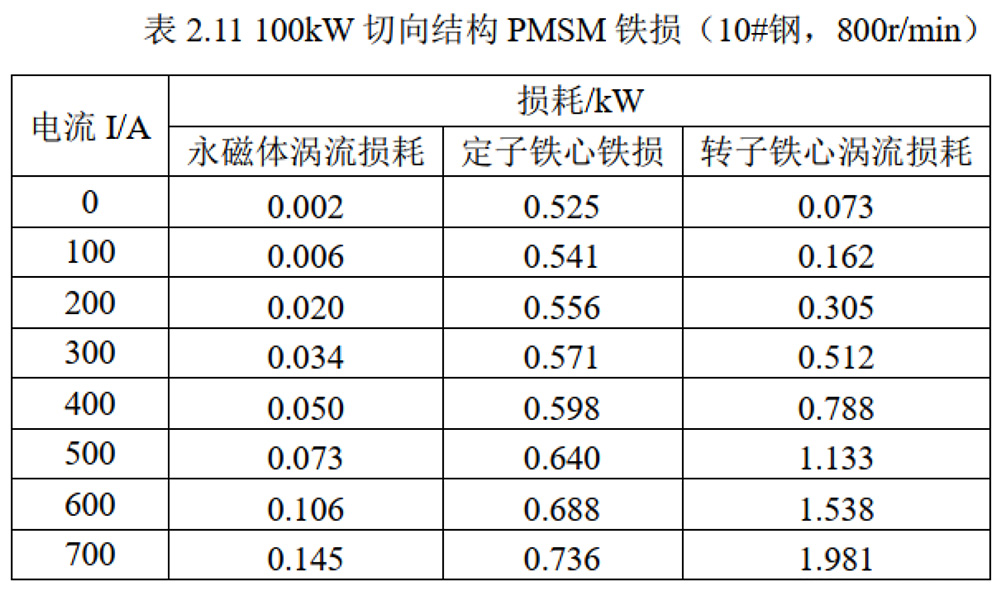

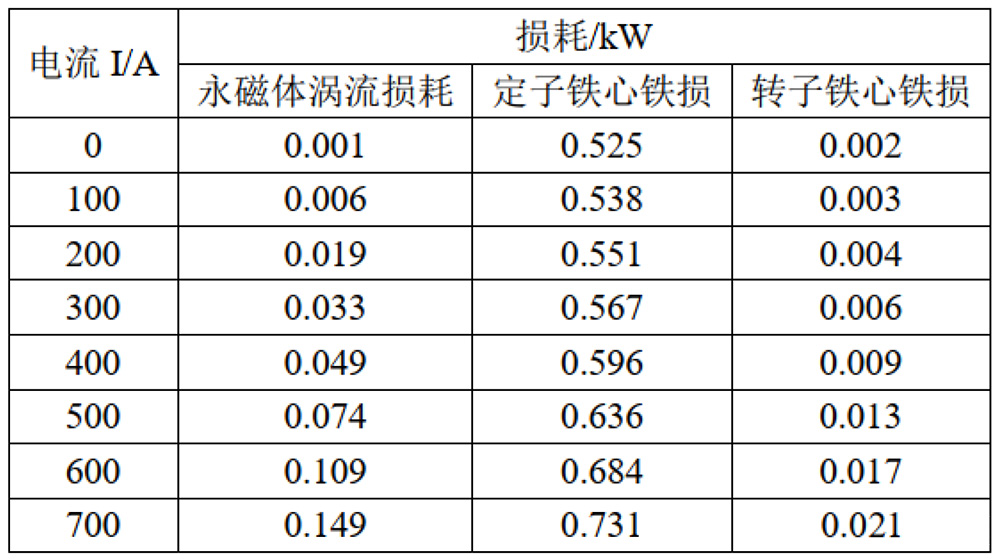

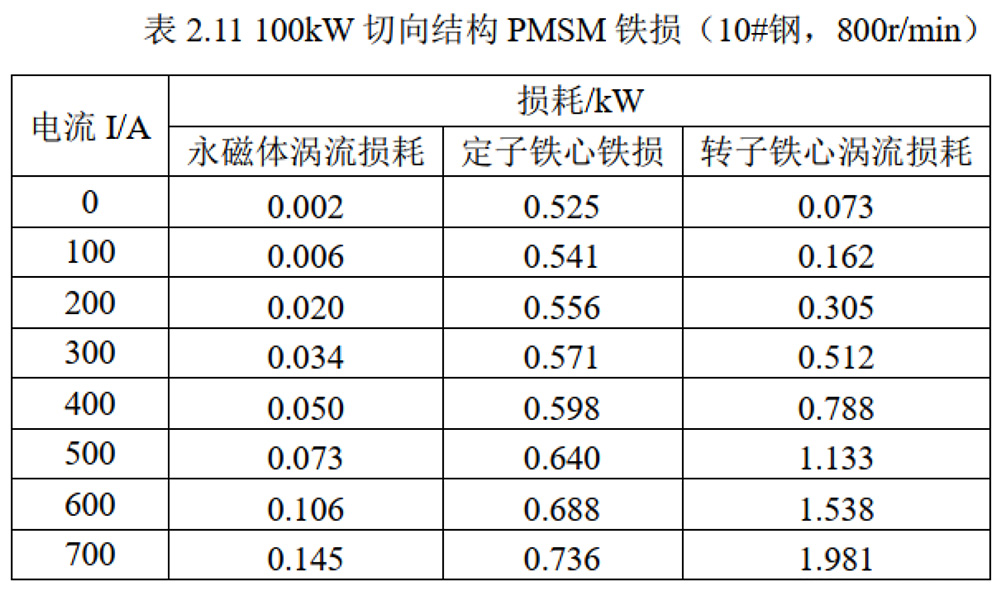

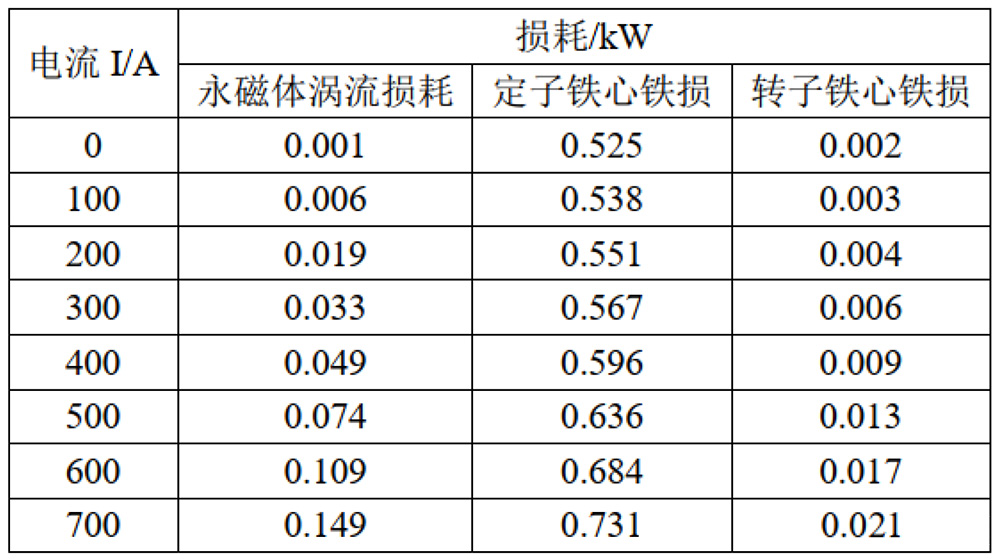

The following is the PMSM iron loss of 100kW tangential structure (DW310_35800r/min)

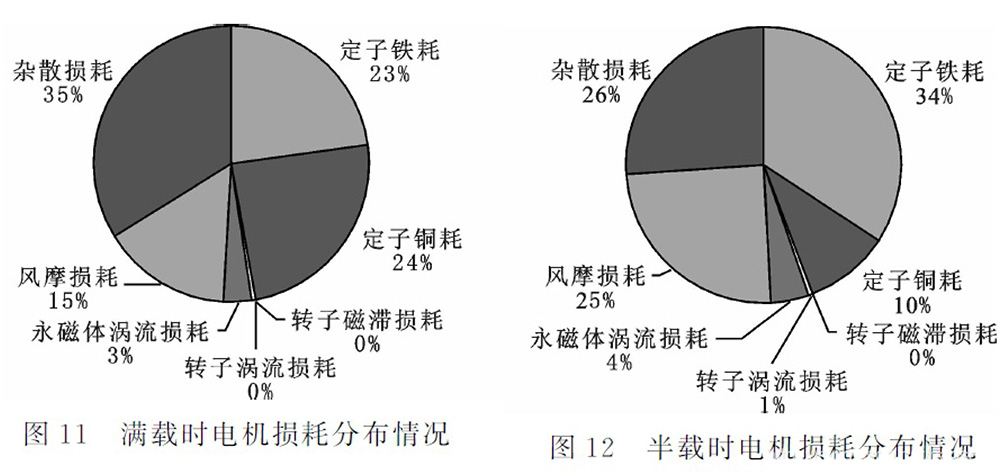

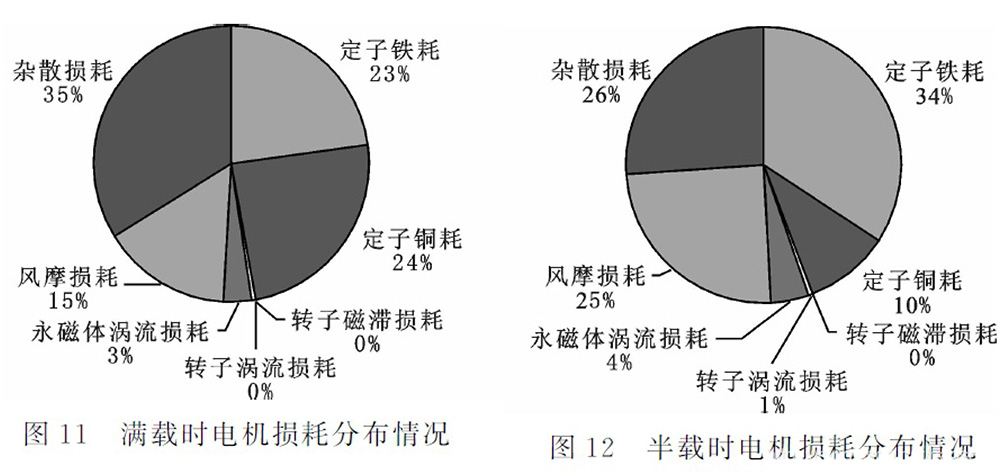

It can be seen that the main stator iron loss accounts for 80% at full load, followed by 17% for rotor magnet eddy current, and 3% for rotor core. (Copper loss and mechanical loss are not considered here), iron loss can be divided into stator iron loss and rotor iron loss. For conventional AC motors, only the iron loss generated by the stator iron core is generally considered, while the iron loss generated by the rotor iron core can be ignored. For permanent magnet synchronous motors, eddy current loss of the permanent magnet is also considered.

For stator iron loss

·The Influence of Armature Current on Iron Loss

Similar to a loaded transformer, the magnetic flux generated by the armature current (primary side) consists of two parts: one is the excitation magnetic flux, and the other is the load magnetic flux. The main source of stator core iron loss is excitation magnetic flux, even during no-load, which is the vast majority of no-load losses. From the above table, it can be seen that as the armature current increases, the iron loss and eddy current loss of each part increase. The eddy current loss of the rotor core and the eddy current loss of the permanent magnet increase significantly, but the change in the stator core iron loss is relatively small, also known as fixed loss.

Sean: So how can we roughly estimate the loss of the motor using no-load and loaded conditions?

Utilizing MultiDriveEC

·Seal all openings and test the no-load loss P0 at rated speed

·Opening the seal, generating airflow, and non load loss P1 at rated speed

·With rated load, the load input at rated speed is P2

Then the fan power is Pfan=P1-P0, and P0 can be considered as stator excitation loss. This value+40% is used as the stator loss at rated load, and the result is converted based on the load curve.

Attachment: If it is a whole iron core rotor, the proportion of rotor core loss will greatly increase. Can only be used for motors with very small capacity.